Press Release

Amnovis enters into IP license agreement with KU Leuven and launches copper 3D printing services with a unique combination of high conductivity and strength

Aarschot, Belgium – November 9, 2022.

Amnovis brings innovation in AM manufacturing by revolutionizing copper 3D printing. An IP license agreement with KU Leuven enables Amnovis to start commercially using a unique copper 3D printing technology, after six years of cutting-edge research. The new technology allows Amnovis to build copper parts with high conductivity and strength, tunable to unprecedented combinations that better serve a variety of industrial applications. Amnovis realizes this by combining excellent laser-absorptive powders with the proven reliability of infrared laser AM systems. Its proprietary process allows Amnovis to manufacture full-density and complex-shaped conductivity components with fine structures as thin as 200 microns.

The close collaboration between Amnovis and KU Leuven, more specifically its SeMPeR and Additive Manufacturing research groups, involves an IP license agreement with regard to a unique copper 3D printing approach. The accumulated know-how pushes copper 3D printing to the next level and enables Amnovis’ customers to benefit from the advantages of this breakthrough technology.

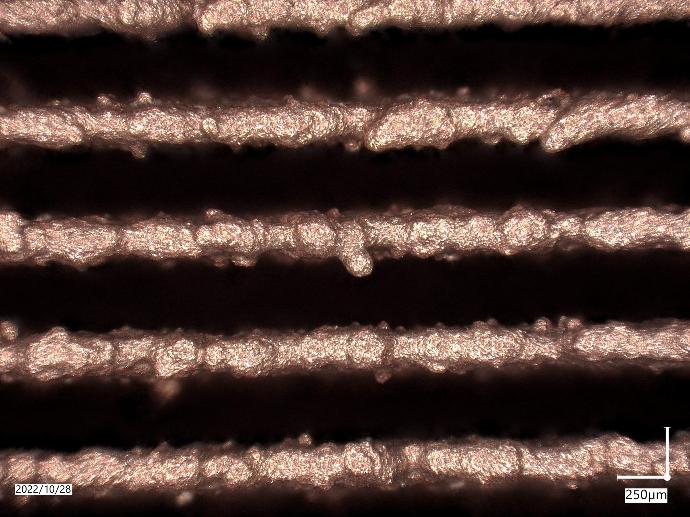

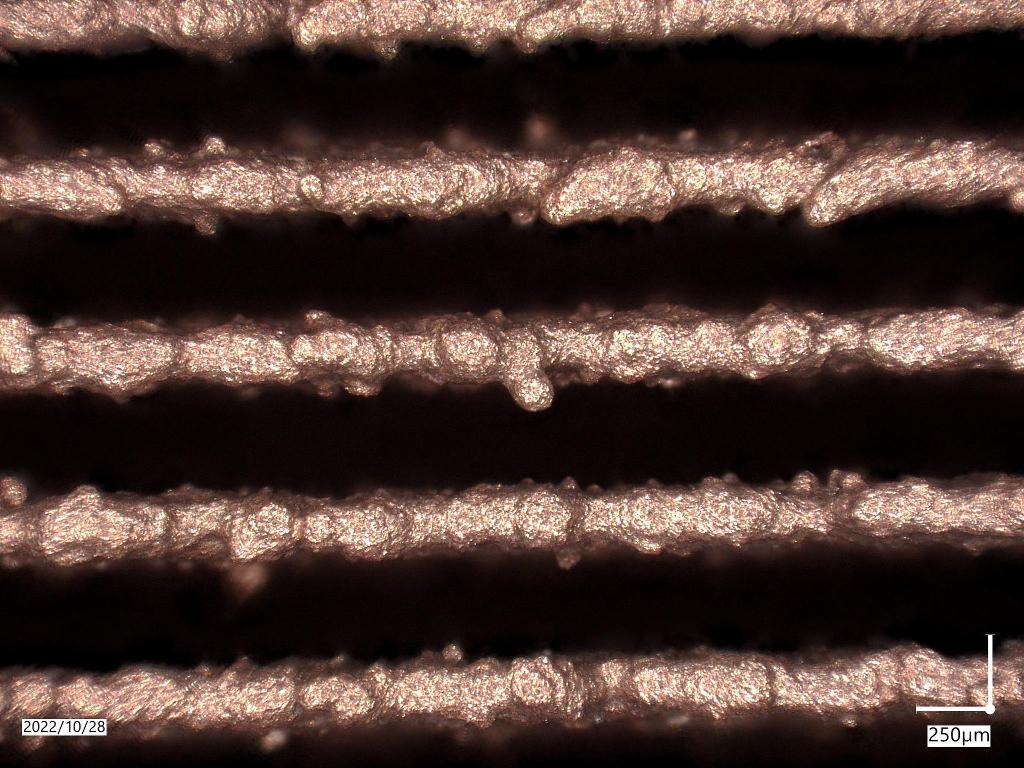

Suraj Dinkar Jadhav, Amnovis' Senior Materials Engineer: "Our copper and copper alloy 3D printing approach is built on a deep understanding of the laser powder bed fusion process (L-PBF). To maximize the use of this renowned and reliable AM technology, we developed excellent laser-absorptive powders based on the KU Leuven technology to overcome the high laser reflectivity and fast energy dissipation of copper material. Amnovis' proprietary process enables to manufacture copper components in a broad, stable, and affordable processing window. It allows full density part builds offering high conductivity and strength, in a specific unprecedented combination tailored to the application requirements at hand. The process supports the ability to form thin-walled and complex-shaped structures with thickness down to 200 microns. The broad processing window of this technology, ensures repeatable and reproducible build quality."

The unique copper 3D printing approach of Amnovis leads to a convincing set of properties. The material density exceeds 99% while the printed material offers improved electrical and heat conductivity. When printing CuCr1Zr material, the electrical conductivity can be tailored up to 90% IACS and the thermal conductivity up to 360 W/(m·K), while a yield strength of more than 500 MPa and an ultimate tensile strength of more than 600 MPa can be achieved, combined with an elongation of 30%.

The proprietary laser-absorptive powders of Amnovis offer excellent flowability and oxidation resistance. As a result, the copper and copper alloy powders reduce powder ageing, improve reusability, and prolong shelf life. The oxidation resistant powders also ensure only negligible oxygen in the final part, which avoids strength degradation after post-heat treatment.

Amnovis illustrates its capability to achieve wall structures as thin as 200 microns and gaps between fine features as small as 250 microns.

The close collaboration between Amnovis and KU Leuven, more specifically its SeMPeR and Additive Manufacturing research groups, involves an IP license agreement with regard to a unique copper 3D printing approach. The accumulated know-how pushes copper 3D printing to the next level and enables Amnovis’ customers to benefit from the advantages of this breakthrough technology.

Ruben Wauthle, Amnovis CEO & Co-founder: " Our proprietary material and process expertise sets a new standard for copper and copper alloy 3D printing. At the same time, we reduce costs by avoiding expensive green, blue and high-power lasers. Providing copper parts with unmatched material characteristics is a perfect example of how we want to innovate AM manufacturing. It enables customers to have superior copper parts printed by Amnovis and achieve stunning performance gains in a variety of applications. For example, just imagine the potential of more efficient 3D printed CPU heat sinks used in the growing number of data centers."

Amnovis will exhibit at Formnext from November 15 to 18 in hall 12.1 on booth D21 shared with Flam3D. At this event, Amnovis will showcase the extraordinary benefits of its unique copper 3D printing capabilities.

Click here for more information.

Diabatix/Amnovis webinar on cooling innovation

On November 10, Amnovis participates in a webinar organized by Diabatix, a leading provider of thermal design software. Cooling design strategies by Diabatix and copper cooling parts manufactured by Amnovis offer a winning combination, as illustrated by a compelling use case:

22% better CPU cooling by combining the generative design of Diabatix and the advanced copper 3D printing of Amnovis

CPU overheating can damage the processor and cause instability in the computer. An efficient CPU cooling system ensures the best experience for the PC's performance. A 3D-printed custom heat sink can offer the ideal heatsink to keep the components within permissible operating temperature limits.

Date: November 10, 2022

Duration: 30 min

Presenter: Ir. Niels Verdijck

Subscribe here (https://www.diabatix.com/webinars/22-better-cpu-cooling-by-combining-generative-design-made-by-diabatix-and-advanced-3d-printing-done-by-amnovis)

DOWNLOADS